View of the building services in the energy cellar. The image shows the cooling water supply for the test benches above.

We have set ourselves a very high bar: our target for a generator module is 10,000 maintenance-free operating hours. This is a record that is almost impossible to beat for dry-running piston machines with kinematic gear. The effort involved is considerable, especially since we are talking about continuous operation at full load for more than a year. We are very motivated by the fact that we have already exceeded 7,000 hours with a Gen70G generator module, which means that our goal is within sight.

Undemanding endurance runners: comulatively more than 200,000 operating hours

“We spare no expense or effort to ensure marketability and to clearly differentiate our alphagamma® units from the state of the art,” says Josef Frauscher, managing director of the company. “Six engines are currently in continuous operation on the test benches. Due to the lack of biogas availability, we are forced to produce the necessary heat energy with natural gas. For this purpose, we use our in-house developed and patented nozzle-mixing burner. They are operated with preheated combustion air, which is preheated from the exhaust gas. This helps us to increase the overall electrical efficiency to over 30% (for the Gen500 machine). Since we consume all of the electrical energy fed into the research building, we generate a small profit in the cost balance, at least in winter, especially since we can use the cooling capacity to support the building’s heating system,” Josef Frauscher continues.

Our test engines are composed as follows:

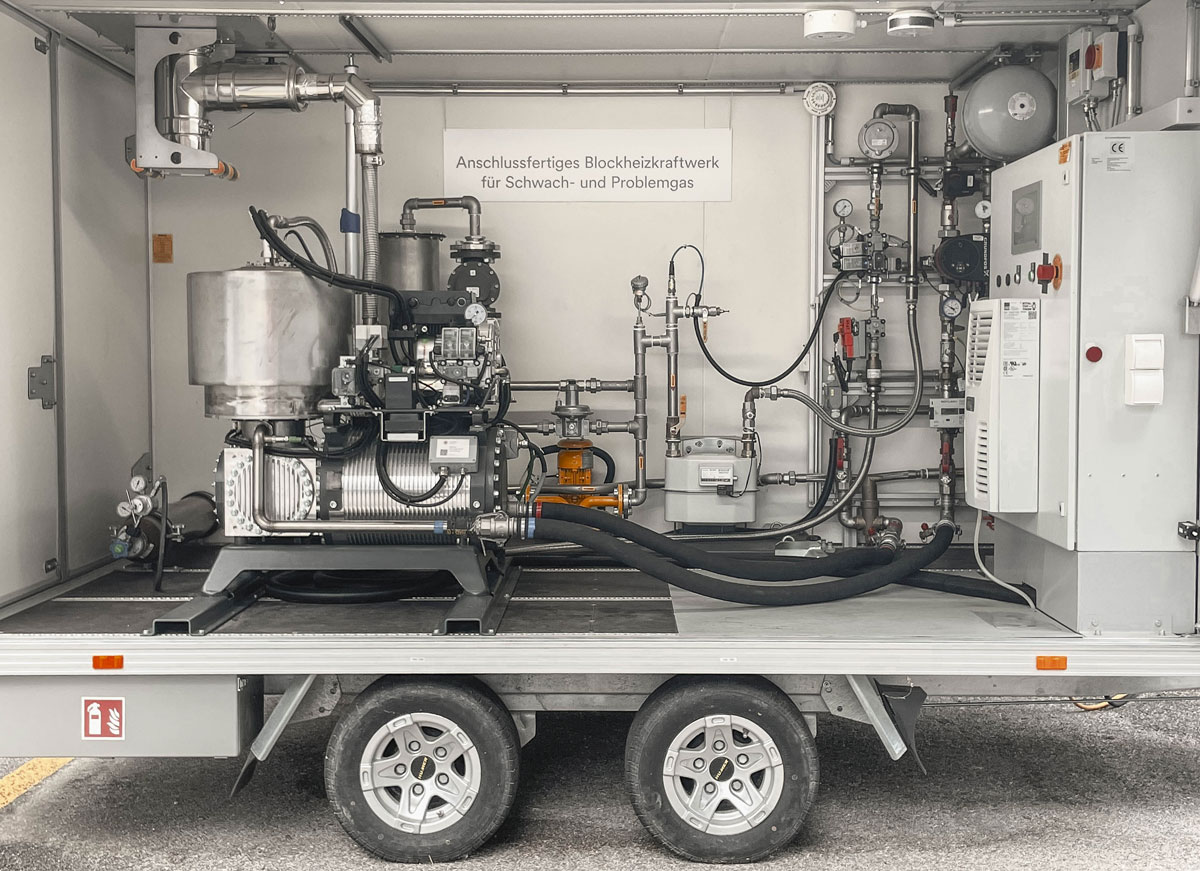

Gen500 CHP, 3x400 volts, 6,5 kW, mounted on a trailer

Gen500 CHP, 3x400 volts, on the test bench

Two Gen70G Micro CHP units, 48 VDC, in the HomeGen configuration

Gen70G Micro CHP, 24 VDC open configuration

Gen70F Micro CHP unit, 48 volts for liquid fuel (diesel)

Summary:

Frauscher Motors invests considerable effort in the stability and endurance characteristics of its alphagamma® units. After years of testing, 7,000 hours at full load can currently be confirmed, resulting in correspondingly longer maintenance intervals in the partial load range. After replacing a few wear parts (piston rings, piston skirt, roller bearings), the customer has a machine that is as good as new for further operation.