We generate electricity from heat

quiet - clean - sustainable.

Our mission

We utilise heat from heating systems, thermal batteries or furnaces to generate electrical energy. We are expanding the combined heat and power market into the low power range and form the basis for grid independence, backup and off-grid systems as well as seasonal power equalisation for photovoltaic systems.

Turning heat into electricity: the key

28 % electrical energy from the supplied heat flow

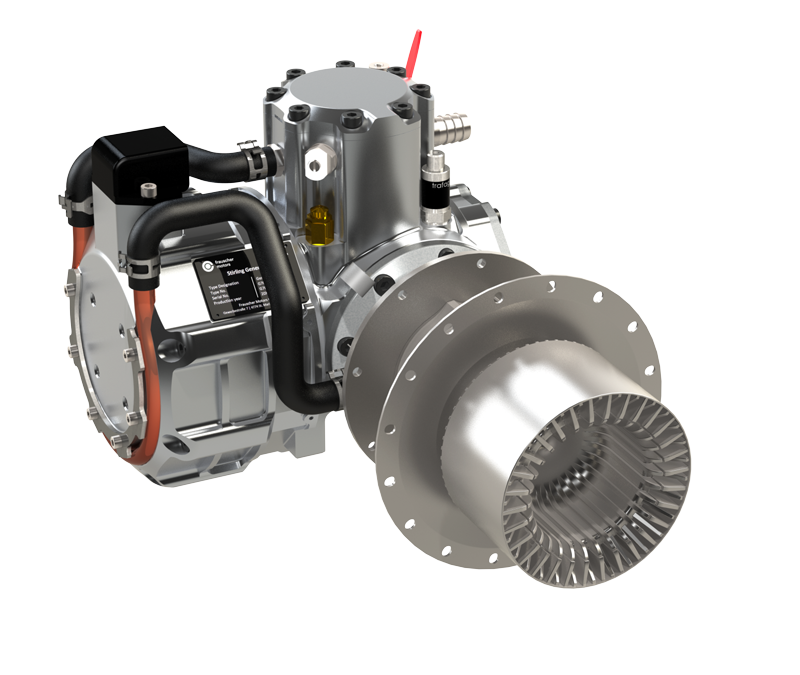

This is made possible by our highly efficient Gen70 generator modules, which deliver electrical power when supplied with high-temperature heat: sustainable, quiet and maintenance-free for up to 10,000 hours.

The technological basis is formed by our motors with the patented alphagamma® principle, the result of more than 20 years of research and development. Weighing just 29 kg, these tireless endurance runners are a world first in the field of Stirling engine technology.

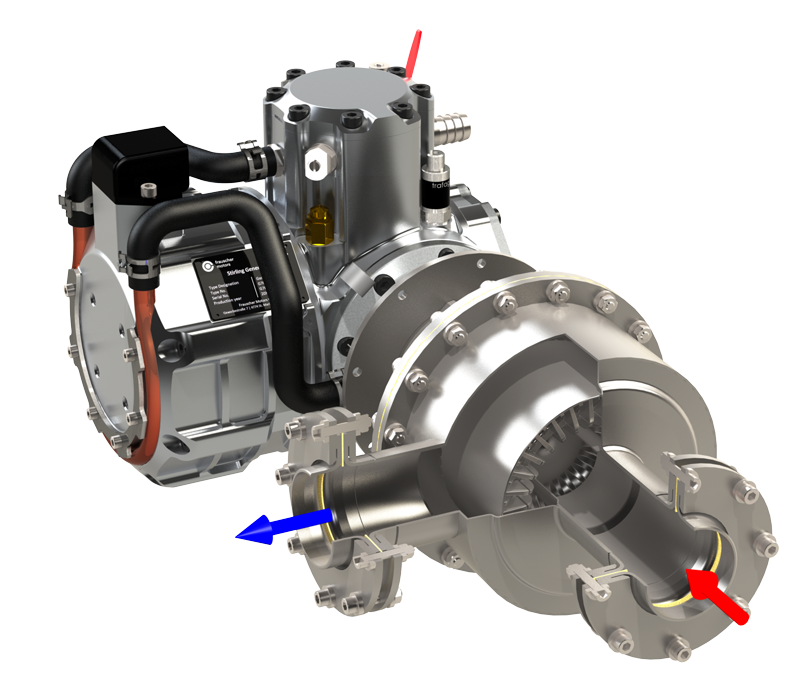

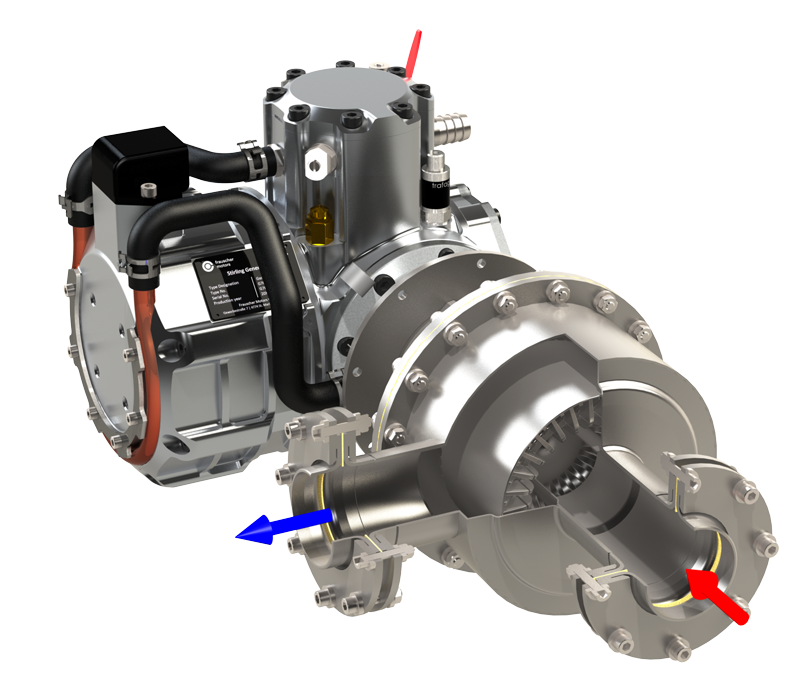

Stirling generator Gen70T, hot gas utilisation variant

A strong quartet for many applications

We adapt our interface to the heat source

Gen70DR:

heat supply mainly through radiation (e.g. pellet firing)

Gen70T:

Heat supply mainly by convection (e.g. hot gas flow)

Gen70C:

Heat supply mainly by conduction (e.g. fluidised bed combustion)

G70G:

heat supply through integrated burner (e.g. gas burner)

The fast track to a micro CHP unit

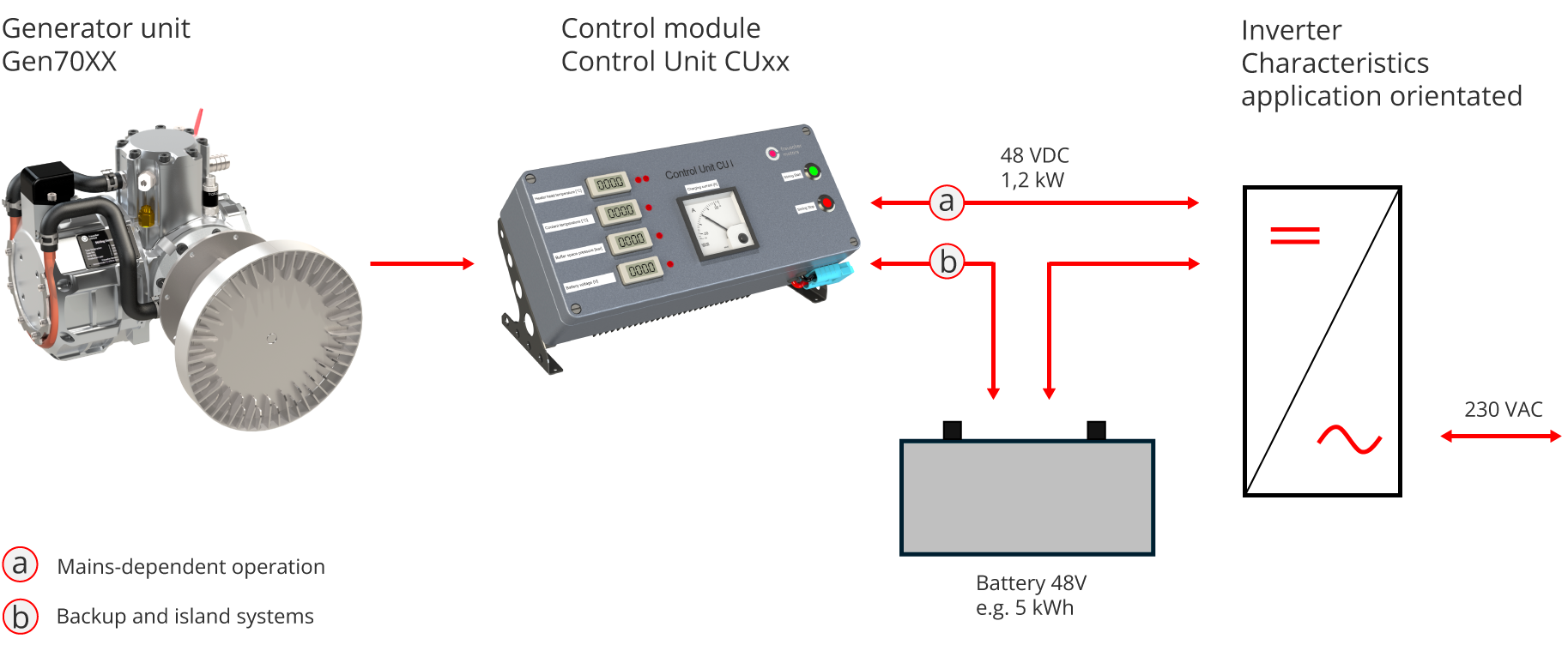

Control module, example Control Unit CU1

The development of low-emission firing systems is a top priority for many companies. The integration of a Stirling generator module would require the burner or boiler control system to be adapted or redeveloped for testing phase, which would entail considerable expense.

Frauscher Motors supports the construction of a micro CHP unit based on a firing system provided by the customer with ready-to-use control modules. The functions include manual or automatic start of the Stirling module when heat is supplied, rectification of the generator current, charge control of the buffer battery and display of the most important operating values including safety functions.

This allows valuable insights to be gained right from the start for stable operation in series applications.

Principle illustration of a Stirling micro CHP unit

The heat exchanger of the Stirling module absorbs heat and starts the generator automatically from a set temperature. The highly efficient synchronous generator immediately supplies a three-phase alternating current, which is rectified by the control unit and forwarded to a suitable inverter (grid-dependent operation) or to a storage battery (backup or island operation).

The motor also generates a cooling water output of approx. 3 kW, which is to be discharged into the heating network or other to heat sinks. Precautions are available for power failures or other disruptive influences.

Our message

The photovoltaic market shows us that generating our own electricity is an attractive prospect. The only disadvantage is the volatile yield, which cannot be satisfactorily balanced out even with large storage units and is of little use in the winter months.

The considerable economic and environmental benefits of micro-CHP units in connection with building heating systems have been recognised in numerous studies and publications.

Frauscher Motors has set itself the task of providing an undemanding element for seasonal or year-round supply with its generator modules. This is independent of whether it is used as the sole power source or in combination with a photovoltaic or wind energy system.

With the heat exchangers specially adapted to the type of combustion and with ready-to-use control modules, a quick entry into micro-CHP technology is possible.

News

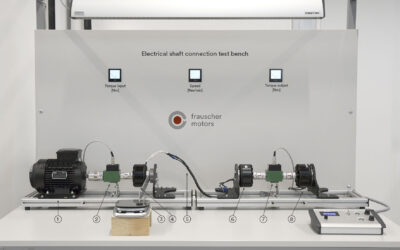

Simulation of a motor-driven heat pump

As part of their thesis, students Marlies Mairhofer and Konrad Niedermayr developed a remarkable demonstration system: a replica of the electromechanical energy chain that can be used, for example, for a hybrid drive in heat pumps. Shortly after its completion, the...

Probably unique in the world: 1000 watts of electricity from a small kitchen stove

You can see it in Bernhard Spielvogel's face – the joy of having successfully transformed a standard kitchen stove into a micro-CHP unit. Indeed, our Gen70DR Stirling generator shows what it is capable of. Simply place the unit with the disc-shaped heat exchanger in...

We are strengthening our management team!

We are expanding our management team and setting a significant milestone in the company’s development: Bernhard Spielvogel has been supporting the company as Partner and Managing Director since the beginning of February 2025. In his professional career to date,...

Contact/Imprint

Welcome!

Do you have any questions or are you looking for specific information?

We are here for you!

Frauscher Motors GmbH

Gewerbestrasse 7

A-4774 St. Marienkirchen

Ph: +43 7711 318 20-0

Email: info@frauscher-motors.com

VAT: ATU64591999

Company registration number: 320883m

Regional court: A- 4910 Ried

Object of the company: Research, development and manufacture of Stirling engines

Image credits: Highfoto-Berghammer e.U.

Frauscher Motors GmbH