alphagamma® process

Small effort – big effect

For many years, we worked on improving the engines using state-of-the-art technology (alpha, beta and gamma processes), but were unable to achieve convincing performance. The high piston forces in conjunction with lubrication oil-free operation caused high friction, high wear and, as a result, only manageable efficiency and service life.

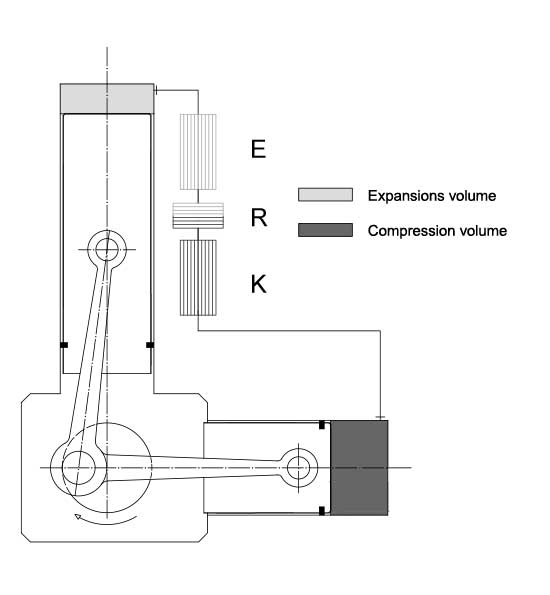

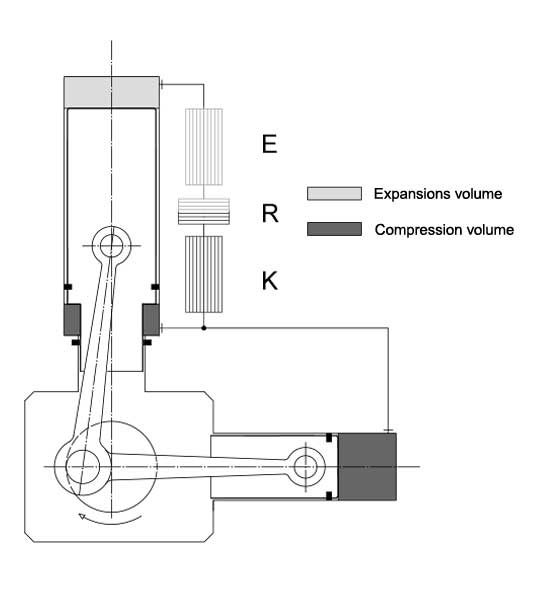

In the course of solving the problem, the idea arose to reduce the piston forces with a stepped piston. The difference, for example, between a standard alpha process and the new alphagamma® process can be seen in the following diagram:

In the alphagamma® process, the ring volume of the expansion piston takes on part of the compression work and keeps it away from the crank mechanism. The smaller effective piston surfaces in conjunction with the optimised phase angle ensure a reduction in piston forces of around two thirds compared to a state-of-the-art alpha process.

Read more about the thermodynamic analysis in which we compare the ‘standard alpha’, ‘alpha optimised’ and ‘alphagamma®’ processes:

Please also take a look at the expert reports:

Expert reports

Dr. Michael Gschwendtner of Auckland University of Technology (AUT) has been dealing with thermodynamic calculation methods, particularly in the area of Stirling technology, for many years.

We have asked Prof. Dr.-Ing. Bernd Thomas of Reutlingen University to analyse the alphagamma® technology and write an expert opinion.

Prof. Thomas has been working with thermodynamic machines, in particular with Stirling engines and refrigeration machines, for over 30 years.

The novelty of the process has been confirmed in the following patents:

- European Unitary Patent No. EP3622167

- German Patent No. 10 2017 109967

- United States Patent US11,725,607

- Japan 2020-513399 (Decision to Grant)

- Canada Patent No. 3096716