Stirling Generator Gen70xx–series

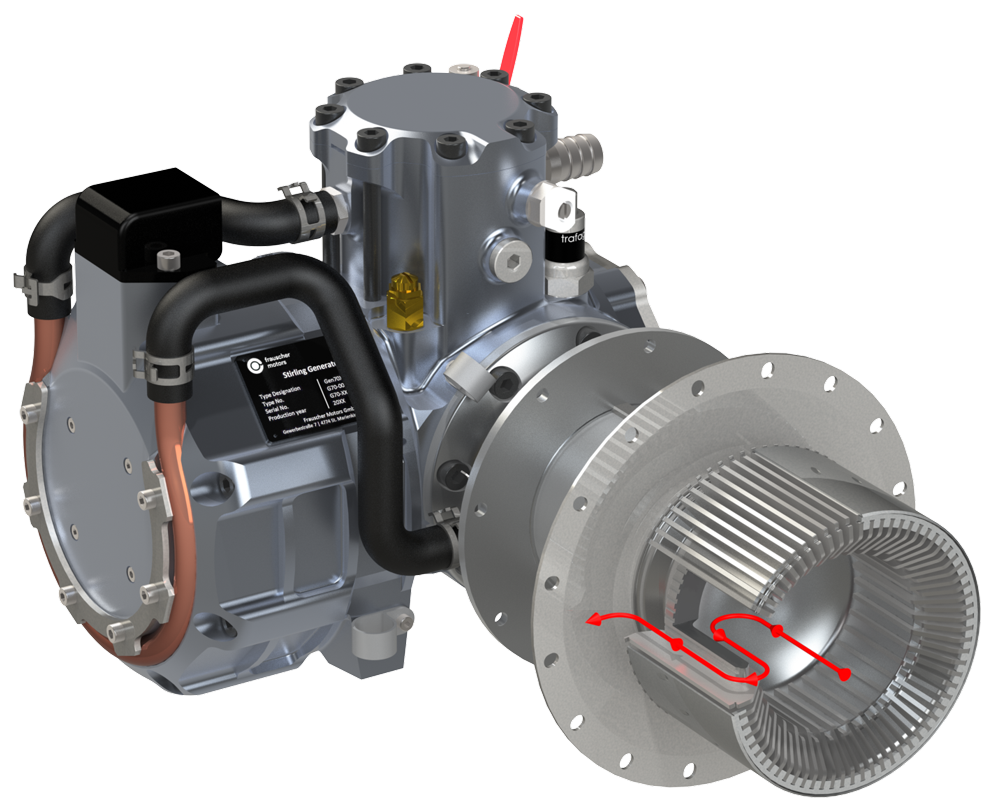

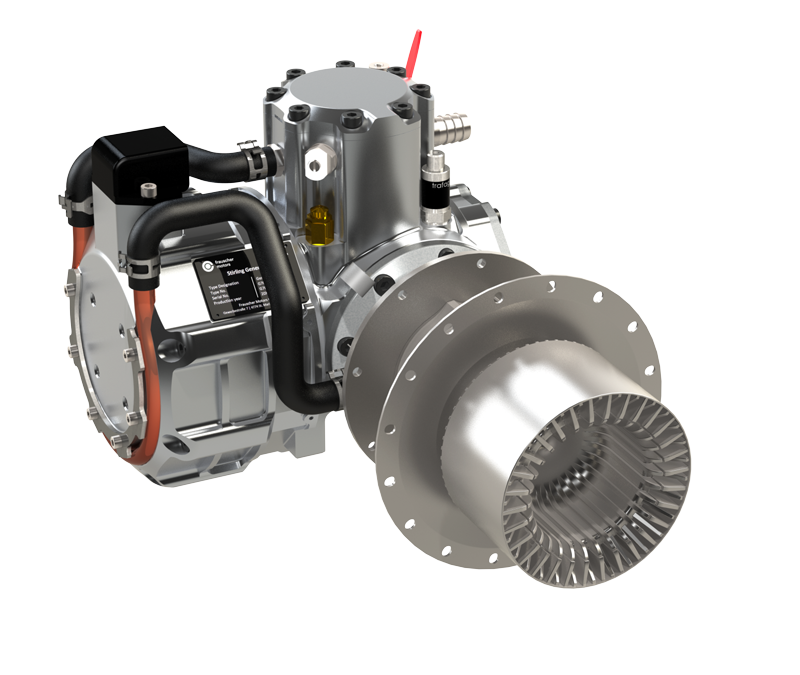

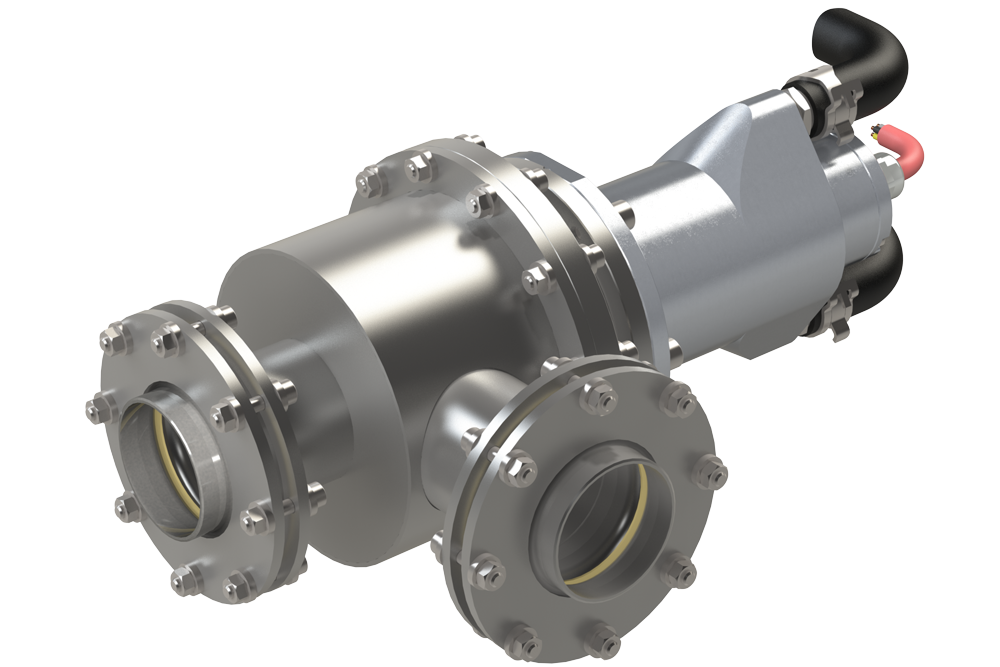

Figure 1: Stirling generator, example Gen70T

Small power pack with impressive features

The Gen70xx Stirling generator consists of an alphagamma® Stirling engine with 70 ccm expansion volume and a 3-phase synchronous generator. The unit is based on decades of research and development with the aim of designing a maintenance-free endurance runner with a high degree of efficiency.

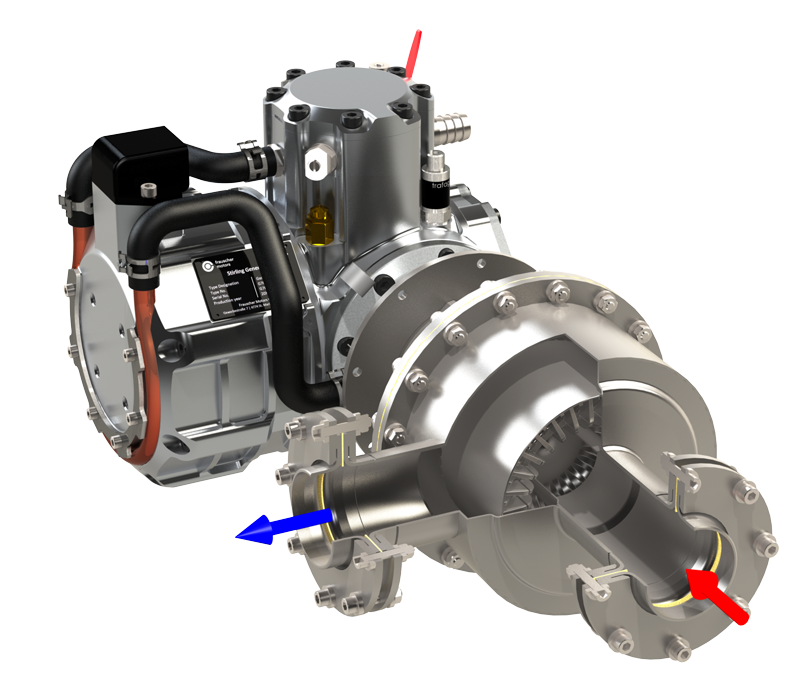

The interfaces (Fig. 2) consist of the heat supply, the cooling water supply, the generator connection and several sensor signals. Several variants of the heat exchanger are available for the transfer of the heat energy, each of which is adapted to the type of heat source. The nominal power of the unit is 1.2 kW at a temperature of 650-680 degrees C at the heater heat exchanger and an output voltage of 55 volts.

Automatic adjustment to the output voltage

The Stirling engine transmits a constant torque to the generator. The rectified 3-phase voltage of the generator can be used to charge a storage battery or can be directly fed into a suitable grid inverter. The speed of the generator is based on the constant torque of the Stirling engine at the output voltage, which, for example, in the case of a lead-acid battery, can be in the range of 48 to 58 volts (end-of-charge voltage).

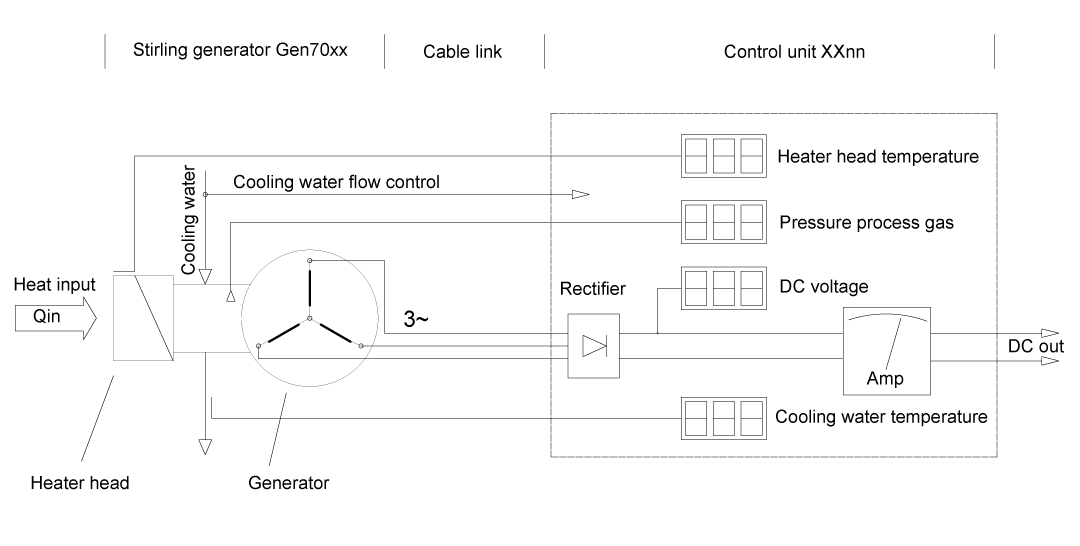

Figure 2: Interfaces of the Gen70xx Stirling generator

Operating data of the Gen70xx Stirling generator

The performance of our motors reveals values that are unique in view of the small size of the motor. The basis for this is the new alphagamma® technology, combined with numerous optimizations.

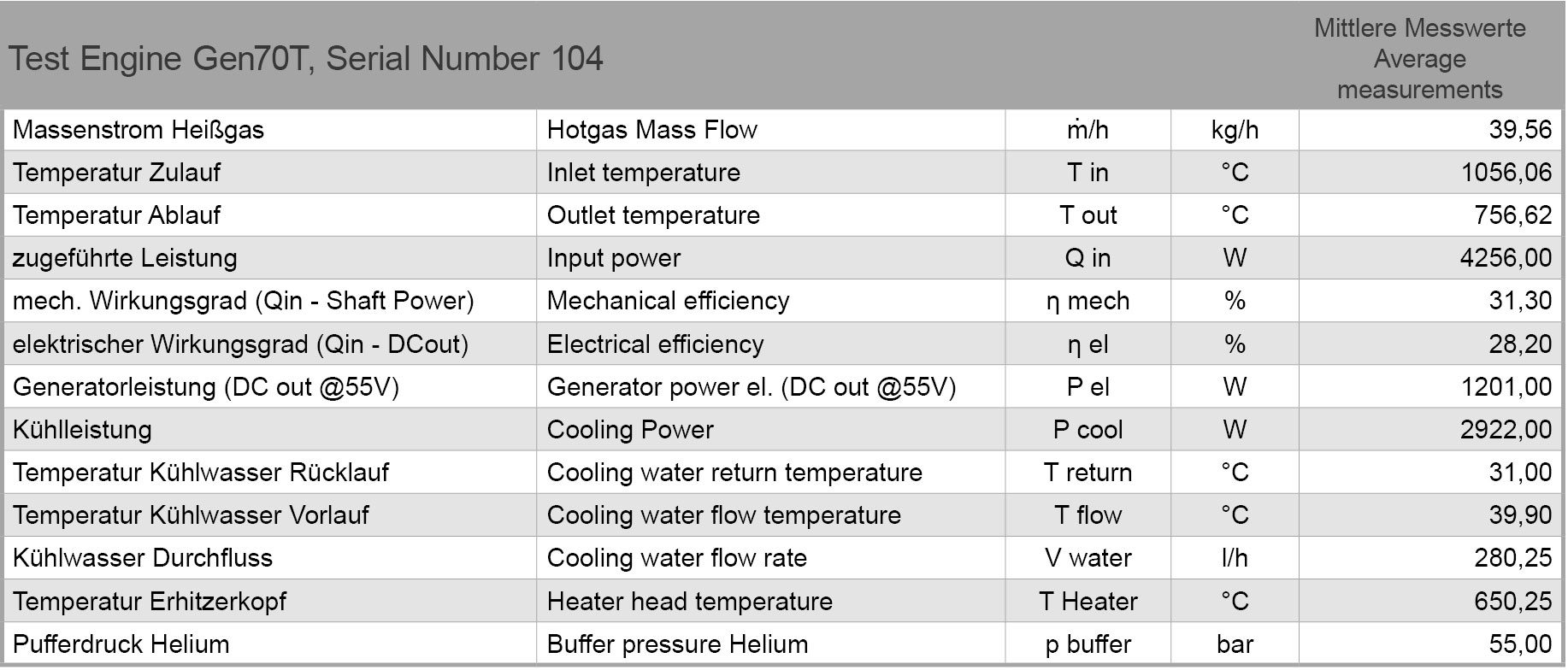

The data shown in Table 1 were taken on the test stand with a hot air flow that is transferred from the heat exchanger of the Gen70T (T for heat transfer by air stream) engine into the process gas of the machine. The data are representative of all heat transfer variants. This can be done by heat radiation, heat conduction or convection using a hot gas flow (see Figure 5).

Table 1: Operating data of the Gen70T Stirling generator

Remarkable performance data

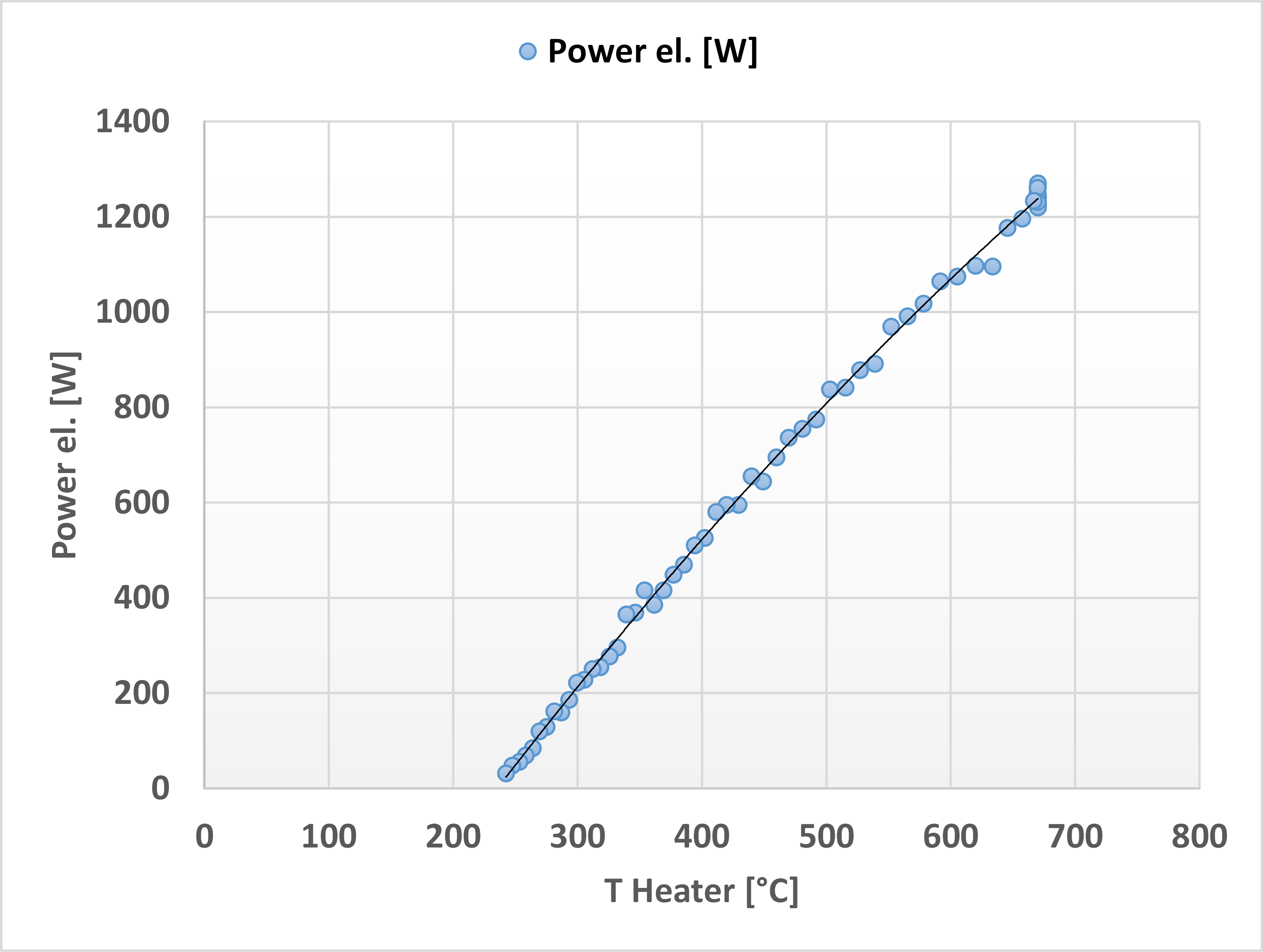

The quality of a Stirling engine can be judged well by the power output as a function of the heater head temperature (Figure 3). The nominal power of 1200 watts is achieved at a head temperature of 670 degrees C. At 500 degrees C, 800 watts are still available. The values at the lower end of the temperature scale are characteristic of the sophisticated technology: the transition from power output to idle takes place at around 230 degrees C. The idle range continues up to around 185 degrees C until the final standstill.

Figure 3: Power output as a function of the heater head temperature

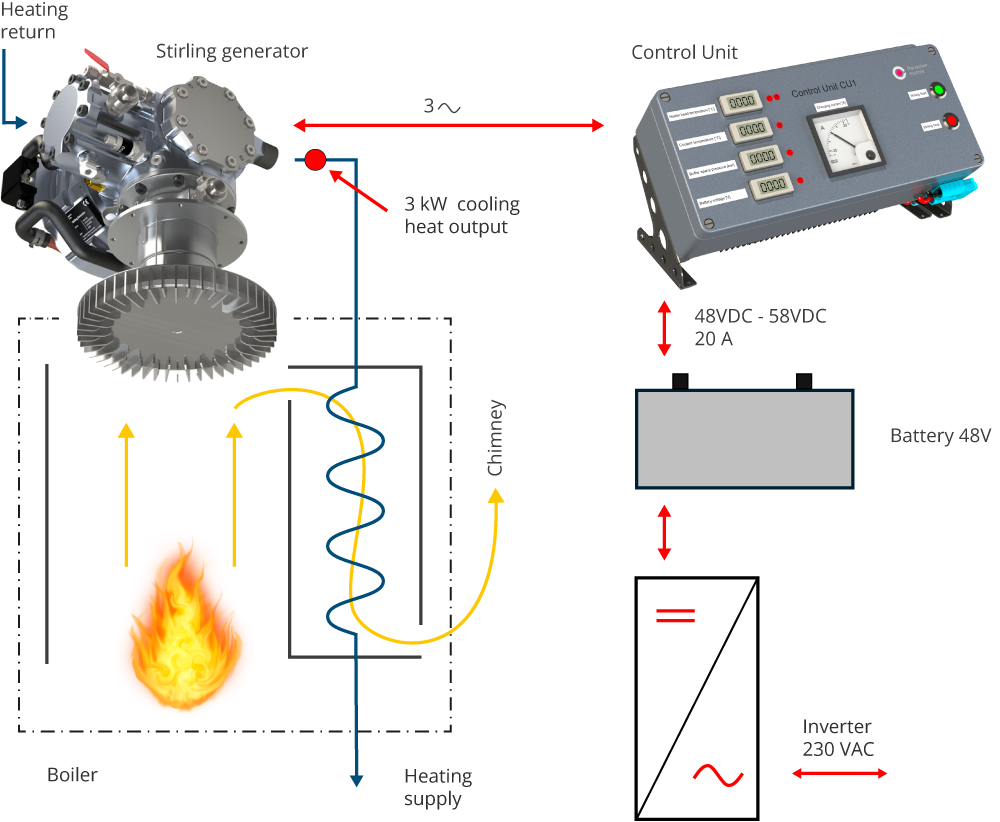

The easy way to a Micro CHP

Operation with a control unit (Control Unit CUxx)

Figure 4

The heat exchanger of the Stirling engine is heated by an external heat source and the Stirling-generator is started automatically when a set temperature is reached. The highly efficient synchronous generator supplies a three-phase alternating current, which is rectified by the control unit and forwarded to a suitable inverter (grid-dependent operation) or to a storage battery (backup or stand-alone operation).

The engine also generates a cooling water output of approx. 3 kW, which is to be diverted into the heating system or other heat sinks. Precautions are integrated for power failures or other disturbances.

After the external heat supply is shut off, the power output drops continuously and the Stirling engine comes to a standstill after a certain time, depending on the residual heat input. As soon as sufficient heat is supplied again, the starting process is initiated again.

Figure 4: Components for Micro CHP

Flexible interface for heat transfer

Figure 5

A sufficient and reliable input of the supplied heat energy into the heating head of the Stirling engine is the basis for a high performance of the micro CHP. This makes the right design of the heat exchanger all the more important, which we adapt to the respective heat source.

Gen70DR

Heat supply mainly through radiation (e.g. pellet furnaces)

Gen70T

Heat supply mainly by convection (hot gas flow)

Gen70C

Heat supply mainly by conduction (fluidized bed)

Gen70G

Heat supply by integrated burner (e.g. gas burner)

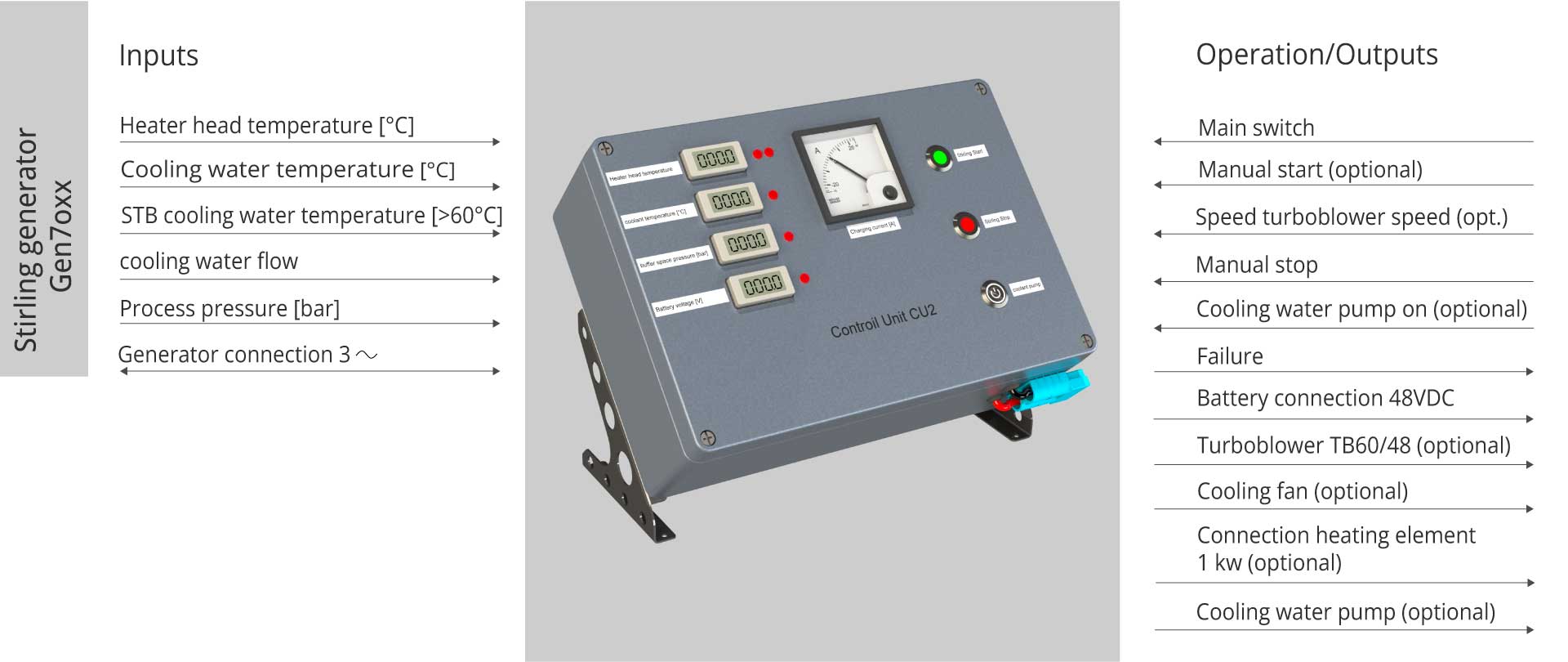

Everything in view: control units CU1 and CU2

The properties of Stirling engines differ fundamentally from those of internal combustion engines. Appropriate monitoring of the process parameters and the interfaces is essential for safe and long-term, trouble-free operation. Our control units CU1 and CU2 were developed for these tasks. The functions and differences between the two versions are listed in the following diagrams.

Figure 6: Interfaces Control Unit CU1

The compact control system with a discrete structure forms the basis for various expansion stages of a micro-CHP unit. Based on the basic functions of the CU1, the function modules for the turboblower, the radiator fan and the cooling water pump can be integrated.

Figure 7: Interfaces Control Unit CU2

Turboblower TB60/48

The water-cooled turbo blower can transport a hot gas stream at temperatures of up to 750 degrees Celsius. It is used to circulate hot air or hot gases from thermal batteries, furnaces or process furnaces. The design was specially adapted for use with the Gen70T Stirling generator, where it is installed on the cooler exhaust air side of the heater heat exchanger.

The blower, which is equipped with 60 mm pipe connections, is supplied with 48 volts via a controller module that allows for stepless adjustment of the speed and thus an optimal adjustment of the gas mass flow and the power consumption. The controller module can be integrated into the CU2 control unit when it is used.

Figure 8: Turboblower TB60/48

Gen70T-HB

Hot air CHP

Figure 9: Hot air CHP Gen70T-HB

This ready-to-connect CHP unit represents our top product from the Gen70 generator series. The cooling circuit is integrated, which is why, in addition to the battery connection, only a hot gas source with a temperature range of 950°C to 1000°C is to be provided. Possible heat sources include combustion gases from furnaces, hot air from thermal batteries or from high-temperature process furnaces. The CHP plant consists of:

- Gen70T Stirling generator

- Turboblower TB60/48

- Control Unit CU2

- Circulation pump

- Cooler radiator

- Cooler fan

Questions?

We will be happy to answer your questions at