Company history

The electronics work table in the basement of Josef Frauscher’s home in the early 1980s years witness to his urge to expand the knowledge he had acquired during the time he was studying Mechanical Engineering to include semiconductor and control technology. As a field worker for a mechatronics company, he was able to successfully put his technical talent to use and steadily gain numerous satisfied customers.

Josef Frauscher ventured into self-employment and founded the sole proprietorship “Hydraulik und Sensortechnik” in Schärding/Inn, Upper Austria. The first products from his own development were inductive sensors for distance measurement for a wide variety of applications.

The precision sensors formed the basis for plumb measuring systems in dam walls. Many dams are still working today with the safety-relevant measuring devices from Frauscher.

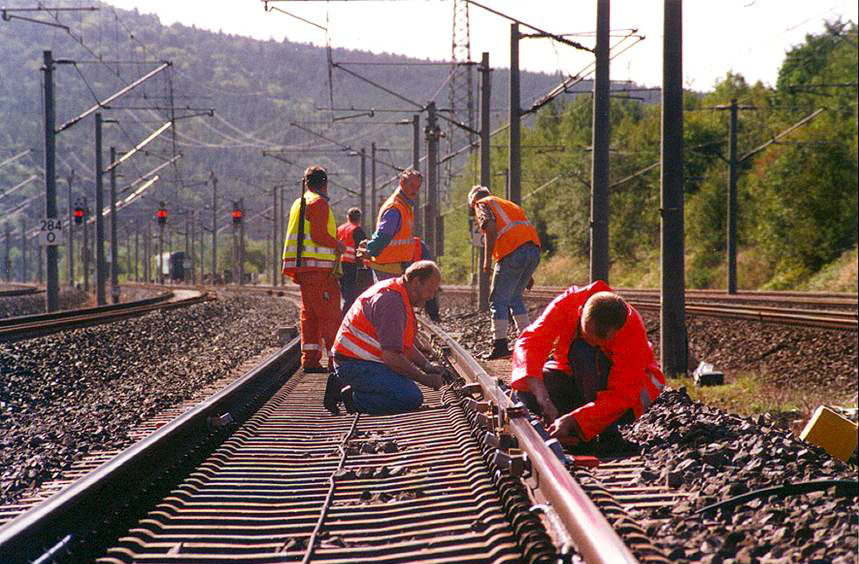

The robust sensors were used in railway tracks. Here is a detailed view of two different sensors for detecting the position of a switch blade.

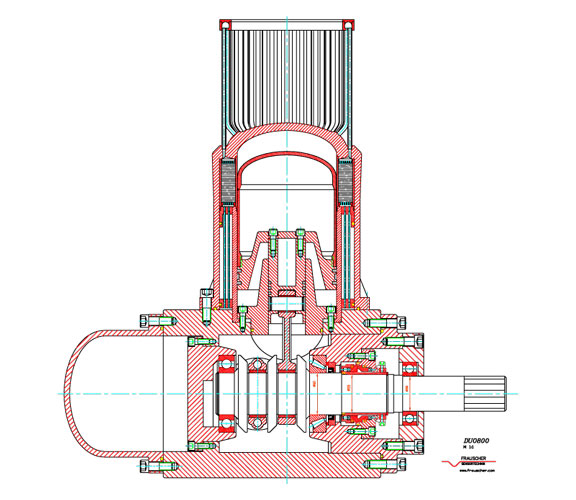

The invention of a new type of wheel sensor for detecting and counting railway wheels marked an important milestone in the further success story of the company, which has meanwhile been renamed Frauscher Sensortechnik GmbH.

Frauscher developed a short range radio system, that could transmit electrical power and information to railway wagons without contact. This enabled the previously dangerous manual manipulation of the unloading flaps of bulk goods wagons over safe distances.

Deutsche Bahn AG decides in favour of Frauscher wheel sensors after numerous practical tests in conjunction with the linear eddy current brake of the new ICE3 high-speed train.

The first company’s own building is established. As a result of the sustainable construction and use of regenerative energies, Josef Frauscher received the Energy Globe Award 2000.

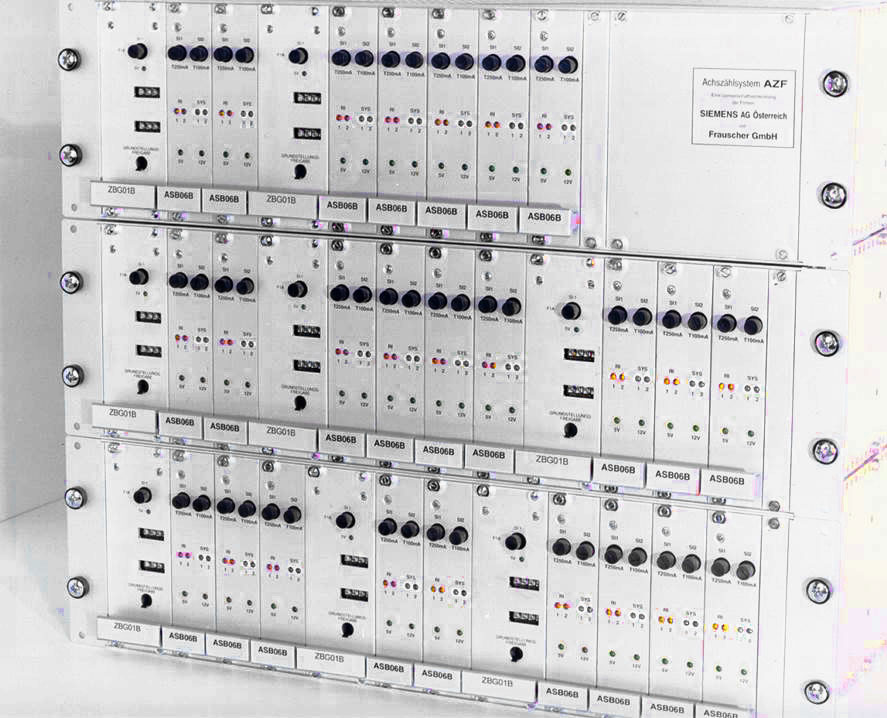

The successful cooperation with Siemens AG Austria in the field of vacant track detection promotes further growth of the company.

Decision to set up the Josef Frauscher private foundation along with the development of a second mainstay in the field of environmental technology. First feasibility and design studies for Stirling engines as part of Frauscher Sensortechnik GmbH.

Remarkable success in exports achieved by Frauscher Sensortechnik prompt its expansion of research and production capacities. The picture shows the beginning of the fourth building expansion stage.

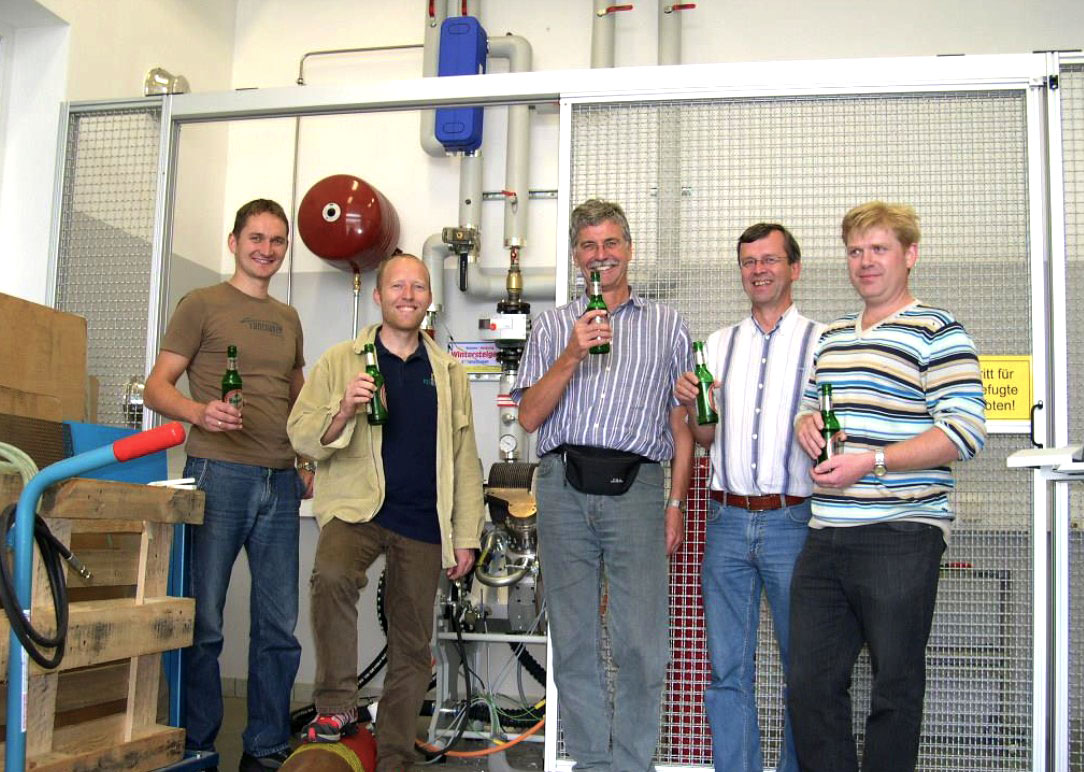

After investing in special manufacturing processes for heat exchangers and setting up a test bench, it was possible to put the first Stirling engine into operation.

Outsourcing of Stirling engine development to Frauscher Energietechnik GMBH (later Frauscher Motors GmbH). Intensification of engine research through the manufacture and analysis of engines using the alpha, beta and gamma processes.

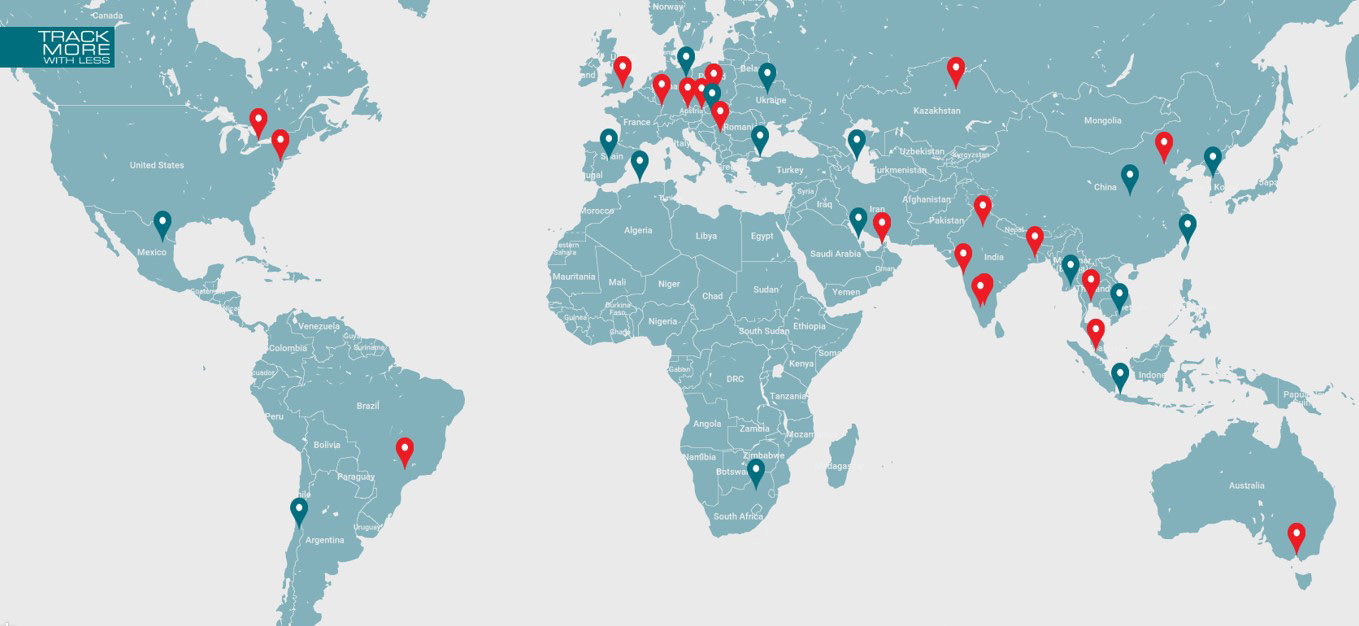

Frauscher Sensortechnik sets an extensive globalisation push by founding sales companies and branch offices in most industrialized countries.

The Frauscher Group sells Frauscher Sensortechnik GmbH with the participation of the management.

Construction of the new technical centre for Stirling engine research with significant investments in test benches and production facilities. The team grows to 14 employees.

With the invention and introduction of the alphagamma® technology, an extreme improvement in the performance of the Stirling units becomes apparent. In the course of a research project for lean gas engines, the first prototypes are tested on the test bench.

The performance of the new alphagamma® engines is confirmed both on the test benches and in external deployment. Two-engine modules with different performance ratings and application variants are being readied for market entry.