The heat pump is a remarkable machine: it is able to convert the energy input up to 6 times into heating energy. However, there is a small downside to the otherwise very sophisticated and quiet mode of operation: on the coldest days, its efficiency (COP = coefficient of performance) drops considerably, especially in the case of air-to-water units, which are the most widespread in terms of numbers; this drop is accompanied by high consumption of electricity, the origin of which can hardly be covered from renewable sources during these periods. This is undoubtedly one reason why, in extreme weather conditions, the heat pump is often supported by another heating source, such as electric heating rods, gas boilers, oil or pellet boilers. However, these additional devices do not make full use of the advantages of the heat pump and reduce the use of primary energy sources only to a manageable extent. A common feature of all these solutions is the loss of heat production in the event of a power failure, with all the consequences this entails.

What has been known for a long time in the larger output range will also work in the future for smaller heating systems for flats and single-family houses: the optional drive of a heat pump with electrical energy as before and alternatively with our innovative Gen70 G(L) unit, that is operated with natural gas, liquid petroleum gas (LPG) or biogenic fuels. In addition to the mechanical power for the compressor, the unit also provides thermal power from its cooling circuit and thus supports the heat pump in terms of a smaller temperature spread. This operating mode provides up to 60% more heat from the fuel used. The fact that the same unit can supply power not only to the heating system itself, but also to electrical consumers in the house, delivers the prospect of a new quality in heating technology. Now every homeowner can look forward to the dreaded blackout scenarios without stress.

Fuel heat effectively supports environmental heat

The synergy effect between the heat pump and the new unit is easily explained. Heat pumps achieve high efficiency at small temperature differences, but this efficiency drops rapidly at outdoor temperatures below 0°C. In this respect, it makes sense to feed the heat pump from the electricity grid during frost-free periods or, even better, with support from a PV system that may be present. At low outdoor temperatures, the Stirling engine can be coupled with the heat pump’s compressor. In this operation, the heat of the engine cooling is added to the output of the heat pump, whereupon up to 160% heating output can be harvested from 100% fuel input. For example, a fuel output of 5 kW for the operation of the Stirling engine increases to a heating output of 8 kW. This value is sufficient for heating low-energy houses or multi-storey flats. The fact that the same heat pump can also be used to cool the rooms is state of the art and certainly a strong argument for fully air-conditioned solutions.

However, the robust Stirling continuous runner has another advantage. During heating breaks, its integrated power generator is able to charge a buffer battery to supply the entire heating system and other sensitive consumers. This operating mode is invaluable, especially in the event of a mains failure, and also creates a wide range of possible applications for off-grid stand-alone solutions. This also includes mobile applications, such as supplying parked transit trucks with heat, cooling and electricity.

Rapid readiness for series production after coordination of the interfaces

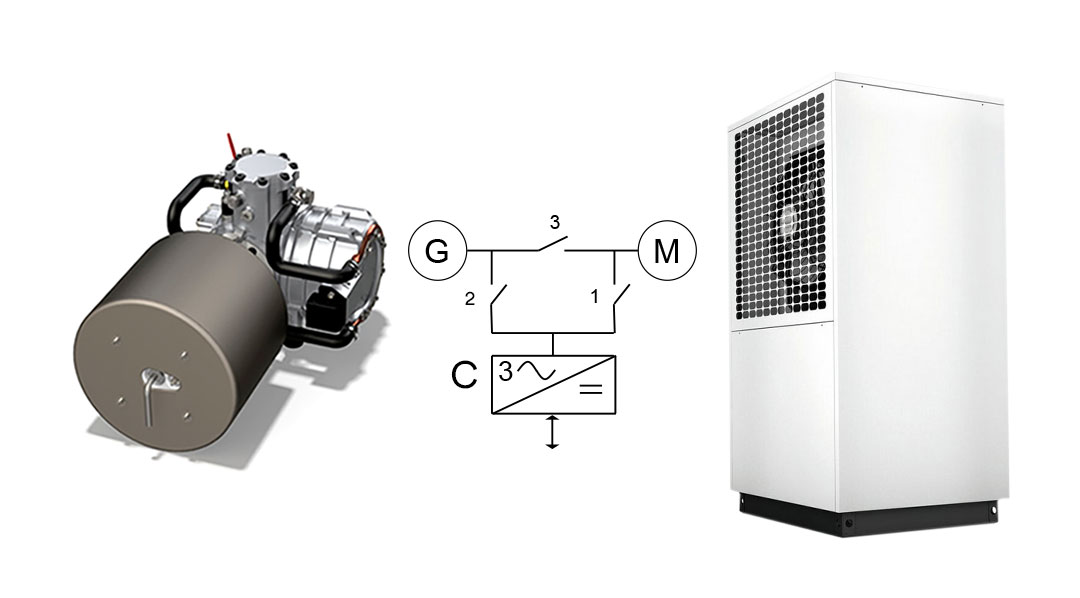

Frauscher Motors has specialised in the development and manufacture of Stirling generator modules. Further research steps in the field of heat pumps or air-conditioning compressors in-house would be completely inappropriate in view of the current high level of product maturity in many companies. Since the interface between the Stirling generator and the compressor unit consists only of a switchable electrical connection, once the performance parameters have been tuned, commercially available components can be used, for example scroll compressors driven by brushless synchronous motors. For coupling an air-conditioning compressor to the Stirling machine.

10/10/2023 by Josef Frauscher

Copyright Frauscher Motors GmbH