The performance of a Stirling engine is significantly influenced by the interface to the heat source. This component is called the heater heat exchanger. The challenge is to allow a high level of thermal energy to flow into a small volume. The heat energy is introduced into the heat exchanger by radiation, convection or a combination of both. Heat conduction to the process gas takes place in the heat exchanger itself, whereby the smallest possible volume (also known as dead volume) is required in this area in order to achieve a usable power density.

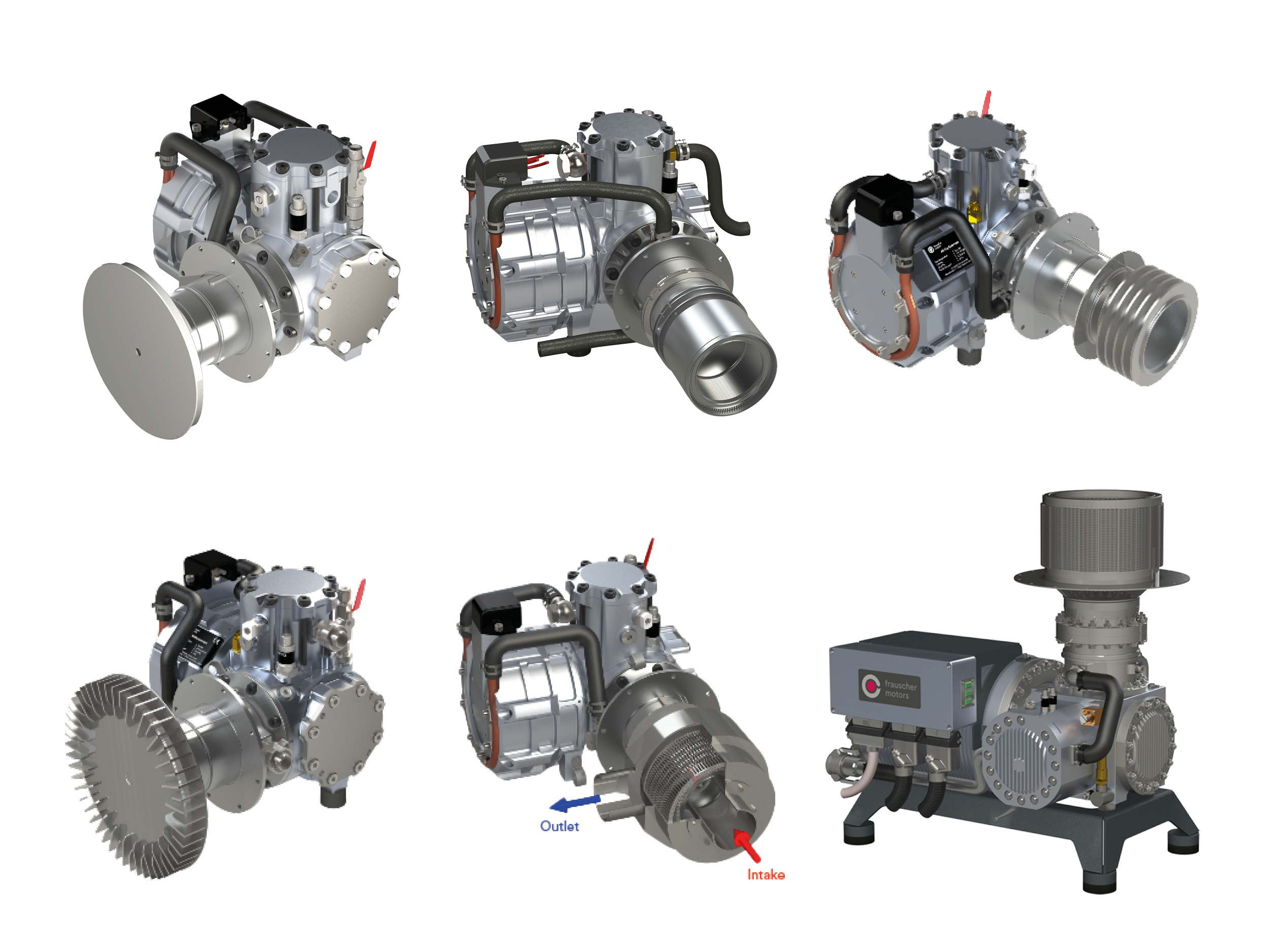

Frauscher Motors has responded to the type of heat source with a range of different heat exchangers. The following heat exchanger variants are available:

- For gas or liquid burners

- For heat transfer by pure radiation

- Design for a combination of radiation and convection

- For biomass flue gases with ash components

- For pure hot air

- For operation in a fluidised bed furnace

- Version for thermal batteries

“With this variety of components, we can react extremely flexibly to the special requirements of our customers. Our manufacturing methods in high-quality vacuum furnaces, which have been tried and tested for years, allow us to realise joining processes that are virtually impossible with other technologies. It is important to bear in mind that these components have to withstand process pressures of up to 65 bar at surface temperatures of up to 800 degrees C, and do so permanently – for many thousands of hours,’ says Josef Frauscher, Managing Director of the company.

Image: frauscher motors