For years, we have been asking ourselves what methods we can develop to utilise our customers’ various heat sources to generate electrical energy. The use of high-temperature radiation as well as the transfer of heat through heat conduction – often in conjunction with convective influence – were frequently included in the lists of inquiries.

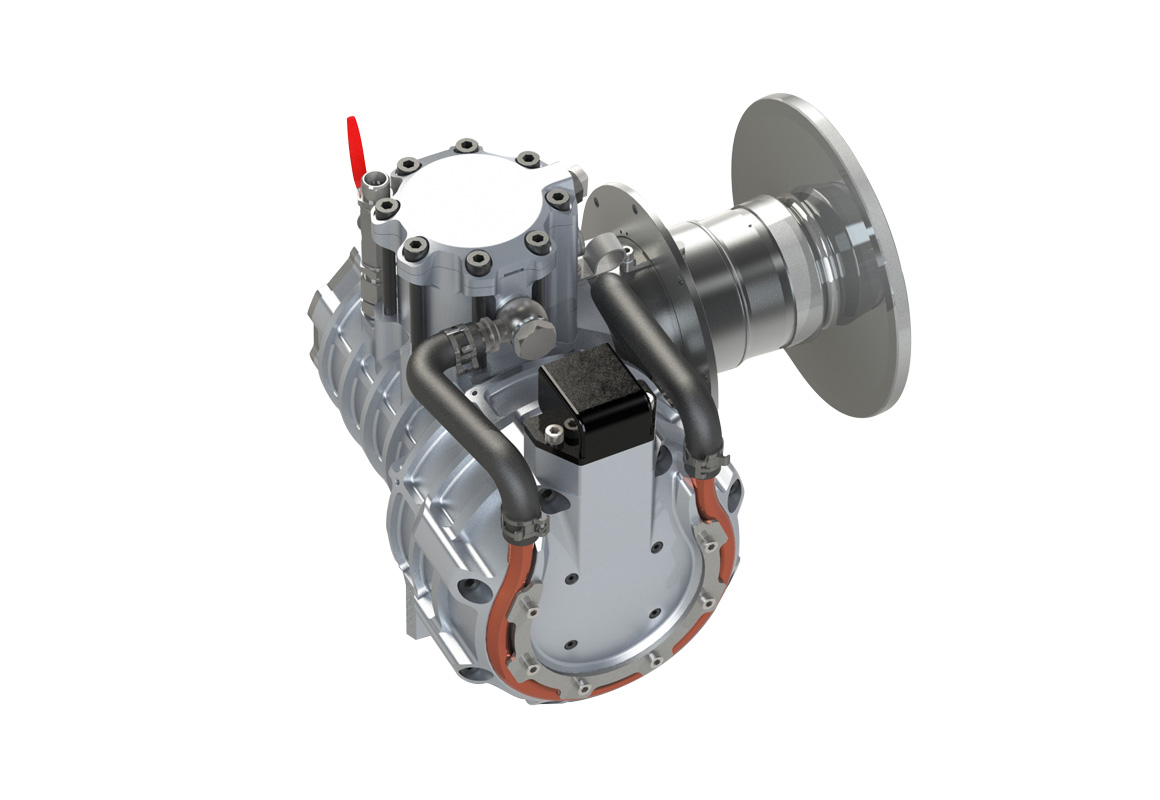

We decided to develop a disc-shaped heat exchanger that is not only capable of absorbing concentrated radiant energy but also heat directly from liquid heat transfer medium. Representative examples of this are thermal batteries, in which liquid metals such as sodium or aluminium are used as heat storage. The disc-shaped heat exchanger of the Stirling genset absorbs this energy and is thus able to supply electricity at any time. A key development goal was a temperature stability of the disc of up to 850 degrees C. This forms the basis for high storage energy, as the Stirling engine still delivers 90% of its nominal output when discharging the storage medium down to about 550 degrees C.

“With our Gen70D unit, we significantly expand the range of applications of our engines, especially since together with the Gen70G, Gen70L and Gen70T versions, a wide range of previously known applications can be covered,” says Josef Frauscher, Managing Director of the company.

Header picture: frauscher motors